A Logistics Solution: Robotic Parking Q&A

Robotic Parking is an automated system is used as a solution to the lack of parking spaces in city centers.

This is the interior of one of the two towers of vehicles that Volkswagen has in its main plant

in Wolfsburg (Germany) full of newly manufactured cars, ready to deliver.

ANSWER: The cost per space of the Robotic Parking System depends on three factors:

a) the size and the layout of the property,

b) the total number of parking spaces needed and

c) the required speed of the system. These three variables are of equal importance in the equation when estimating project costs.

Overall development cost, not construction cost, is the most important factor. A Robotic Parking System will ALWAYS result in lower development cost / capital expenditure and generate a higher return on investment as compared to a conventional parking garage in any urban setting.

Recent turnkey prices have ranged from an average of $20,000 to $30,000 per space for a mid-size garage and depending on the area.

There is a very large difference between pricing for a fully turnkey robotic garage as compared to pricing for just the automated system. You should make sure you understand exactly what is included in any price quotes you receive.

Taking a turnkey construction cost of a Robotic Parking System of $22,000 per space and factoring into the equation the reduced cost of land (or alternately the floor area gained), the adjusted actual construction cost can be as low as $10,000 to $16,000 per space depending on the value of the land and/or floor area.

* Urban setting is defined as anywhere the land price is above $80 USD / SF.

(Source: Professor Dr. D. Sollohub of Rutgers University)

ANSWER: Robotic Parking Systems use an average of 50% less land area for the same amount of parking as compared to conventional concrete ramp style garages.

ANSWER: The time it takes drivers to retrieve their car depends upon where the car is parked inside the system; however, the minimum time needed is 1 minute, and the maximum time is 3 minutes. But, this is not the most important factor.Much more important is the peak traffic capacity (or throughput) of the system. This means how many cars can be processed in a given time frame, let’s say in 30 minutes. If 10 customers retrieve their car at the same time, how long does customer number 10 have to wait until he gets his car?

QUESTION: What is the height of the levels in the Robotic Parking System?

ANSWER: The Robotic Parking System differentiates between sedan vehicles and SUV’s, and each vehicle category will be stored in different levels. Therefore, there are two different heights of levels – 2159 mm / 7.1 ft to accommodate sedan cars and 2692 mm / 8.8 ft to accommodate SUV’s. These are “floor to floor” heights. The total number of levels can add up to 20 or more in specific cases.

Car height for sedans typically is 1534 mm / 5 ft and 2057 mm / 6.75 ft for SUV’s.

QUESTION: How long does it take to build the Robotic Parking System?

ANSWER: The time it takes to build a turnkey Robotic Parking System depends on the size of the project; however, it can typically be completed between 10 to 14 months.

ANSWER: The Robotic Parking System can be stand-alone, below a building or above a building as long as there are access routes to the terminals. Some 3D models that show the versatility and flexibility of the Robotic Parking System are available. Click here to take a look at the Robotic Parking Systems BIM (Building Information Modeling)

ANSWER: No, the facade and roof can be attached to the Robotic Parking System steel or concrete supporting structure and do not need be free standing.

However, special connection details must be followed.

QUESTION: How much power is needed to park and retrieve 1 car?

ANSWER: It requires 3Kw/Hr to park and retrieve the car – including all auxiliary electrical needs like lighting, air conditioning etc.

ANSWER: Each entry / exit gate (terminal) can handle 45 cars in one hour. This is derived from an average time measured that depends on the human interface – meaning how long it takes the customer to drive the car into the terminal, get out and take the ticket so that the system can process the car.QUESTION: Is the Robotic Parking System supporting structure in steel or concrete?

ANSWER: The Robotic Parking System can be used in both a steel structure as well as in a concrete support structure.QUESTION: How many parking spaces can be built with a Robotic Parking System?

ANSWER: Due to the modular flexibility of the Robotic Parking System, automated parking structures are designed and built from hundreds to thousands of parking spaces.QUESTION: Is the Robotic Parking System suitable for handicapped persons?

ANSWER: Robotic Parking Systems designed the standard entry / exit terminals to be suitable and comfortable for the handicapped.

The minimum width of each terminal is 4755 mm / 15.6 ft.

Must be compatible with the requirements of the ADA – American Disability Act.

QUESTION: How many rooms typically needed to operate a Robotic Parking System?

ANSWER: In addition to the actual storage volume:

- a Control Room

- Lobby

- Electrical Room

- Pump Room

- Generator Room

- Storage Room for spare parts are needed

QUESTION: What makes a Robotic Parking System more “green” or environmentally friendly?

ANSWER: Robotic Parking Systems offers a more eco-friendly parking solution by:

(a) Using 50% less space to park the same number of cars as a conventional garage. Because the amount of land used affects sustainability issues, including development density and maximizing open space. Architects and developers can now use less space for parking. Moreover, they now incorporate more green space and open areas to meet certification requirements.

(b) Reducing the traffic congestion and accompanying pollution. Multiple studies have reported that 30% to 50% of traffic congestion in city centers. Seems that traffic is generated by drivers searching for a parking space. A report from IBM Global Business Services stated that congestion costs up to 4% of GDP. Additionally, In the US, congestion in urban areas results in annual costs of 4.2 billion hours of wasted time and US $87 billion from wasted fuel and lost productivity. The high-speed, efficient automated parking system also ensures that even the largest parking design can be made smaller while still ensuring fast retrieval times for clients.

(c) Reducing pollution inside the garage by using electro-mechanical automated parking machinery to move cars into parking spaces. No cars run inside the garage. There is no driving up and down ramps and through aisles in search of a space.

This will significantly reduce the emissions of:

- harmful gases

- reduces the carbon footprint

- increases carbon credits

- ensures an environmentally clean parking facility

Did you know that tire and brake dust pollutants are more toxic than all the exhaust related emissions?

In a 750 space Robotic Parking System, 37 tons of tire dust and 3.7 tons of brake dust pollutants are eliminated.

This is done by using electro-mechanical machinery to move cars inside the garage.

WELCOME TO OUR COMPANY FAST EQUIPMENT!

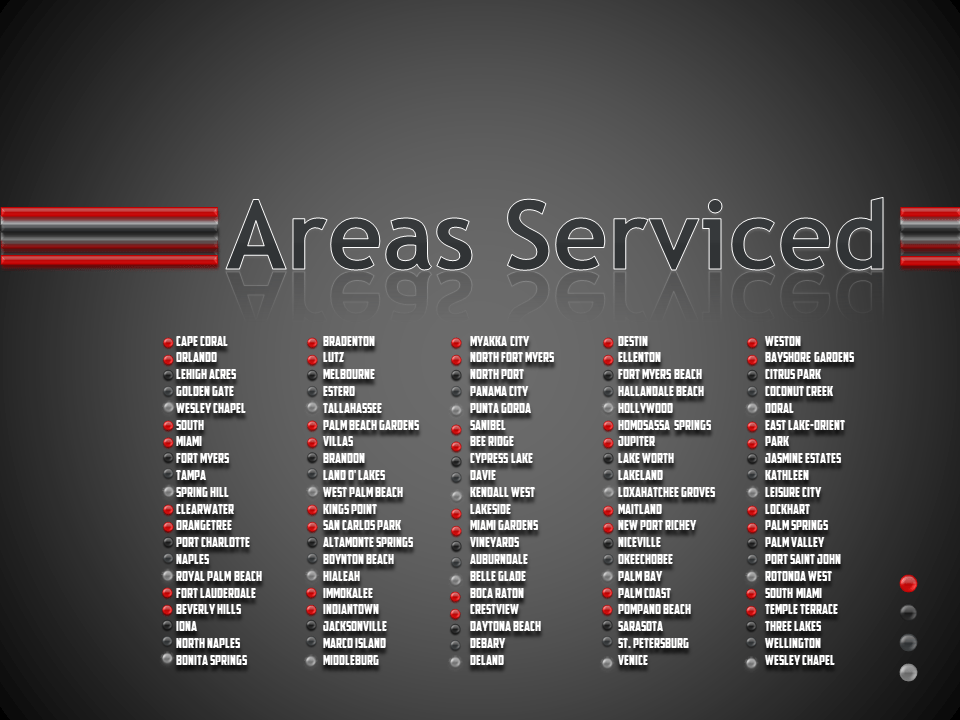

Fast Equipment is the one-stop shop for all your Automotive Lift, Service Tools & Equipment needs in Florida. In addition, we provide vehicle garage parking solutions as well as quality automotive lifts and service equipment for residential and commercial establishments. Since 1979, we’re recognized as apart from the rest. This is because we have a constant clientele of repeat business and customer referrals through word-of-mouth advertising as well.

We are proud of our solid array of accredited commercial and residential customers. From homeowners and single-bay shops to high volume fortune 100 companies – all whom depend on us for their car storage, automotive lifts and service equipment needs. Not to mention, we keep them all working smoothly!

SERVICES WE OFFER

Whether it’s a new construction project, business expansion or updating equipment – Fast Equipment guarantees quality service. We also pride ourselves on our ALI-certified technicians who place emphasis to go over and above to meet the satisfactory expectations of our clients. In any way possible, they have all have helped to establish a reputation for us as the finest service department in all of Florida!

Fast Equipment provides garage repair and car storage parking solutions to over 100 Automotive Dealerships and repair facilities including:

> National Retail Super Centers

> Large Fleet Service Centers

> Government Agencies

> Local City & State municipalities

> Local Schools, Colleges & Universities

> Sports Stadiums and Concert Arenas

> Airports and Helipads

> Police and Sheriff’s Departments

> Hospitals, Institutions and Health Clinics

… and more!!!

WE INSTALL AND SERVICE EVERYTHING WE SELL!

Including:

- Vehicle Lifts

- Surface mount and in-ground

- New installation or R & R

- Motorcycle Lifts

- Overhead Oil Systems and Hose Reels

- Lube Tanks & Pumps

- Air Compressors

- Air Conditioning and Refrigeration Machines

- Tire Balancers

- Tire Changers

- Collision Repair

- Brake Lathes

- Tool Storage

- Used Equipment

- Everything and more!!!!

Maybe you know what kind of lift and automotive equipment you’d prefer. We likely have the selection you need to get your custom garage up and running.

Consider our 4-post lifts, 2-post lifts, mid-rise car lifts or home garage lifts. Compare the features, benefits and specifications of our lifts to find the one that works for you.

Contact us anytime for a 10-minute consultation to discuss how to save on your car parking and storage solutions.

Please call us at 1-800-225-7234, or request a quote HERE.